Assignment: Create a backdrivable robot with 3 degrees of freedom.

In industry, robots can be dangerous. If a human happens to be where a robot wants to move, chances are the robot will push through the human, potentially injuring them. One way to make such robots safer is to make their limbs backdrivable. Backdrivability provides the ability to push back against the robot actuator without significant resistance. This would mean that a human would be able to stop a moving actuator with ease and without any risk of injury.

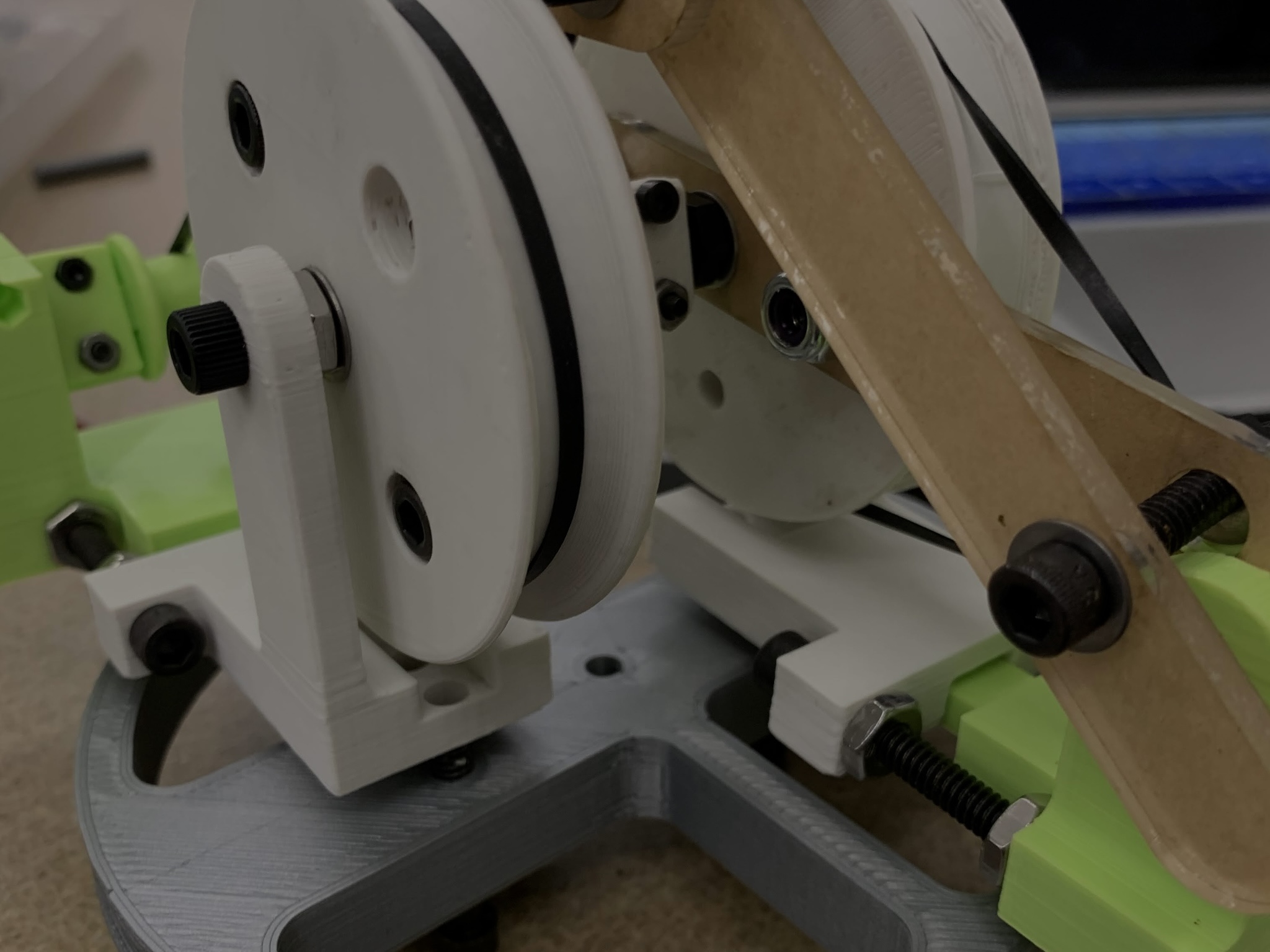

To create a robot that had 3 degrees of freedom, we broke the project into 3 parts, each to be made by a member of the 3-person team. I was tasked with fabricating the dual motor mount. This motor mount was meant to manipulate the control arms of a 4-bar linkage around one axle, while providing a 5:1 mechanical advantage without any deadzones or cogging caused by gears. This was done using a belt-pulley system using high-tension elastic bands, as well as a screw-based tensioning system to tension the band.

To implement the backdrivability, we used low torque mini DC motors that were geared for enough torque to actuate limbs with force, but not enough to push through human resistance.

The project was ultimately abandoned due to time constraints, but I managed to get my 4-bar linkage working with 8mm drone motors and an Arduino MKR motor shield. Below are some images of my motor mount (green and white parts) mounted on a rotating base plate made by a teammate (gray).

A video demonstration of the product is shown below.